The ink prints circuits that change from hard to soft. This helps make devices for wear, medical use, and robots that fit and work better.

Variable-stiffness electronics switch between rigid and soft modes. Gallium, with different stiffness in solid and liquid forms, is a key material but has issues like high surface tension and phase changes. Researchers from KAIST and Seoul National University created an ink to print variable-stiffness circuits at room temperature, enabling devices that adapt stiffness for wearables, implants, and robots.

The new ink enables printing multilayer circuits like PCBs that change stiffness with temperature, opening new uses in electronics, medical devices, and robotics. Traditional electronics are either rigid or soft, limiting comfort or control. Variable-stiffness electronics that adapt to use are becoming more important.

To tackle this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is stiff, while its liquid form is soft and fluid. Using gallium in electronic printing has been limited by its high surface tension and instability when melted.

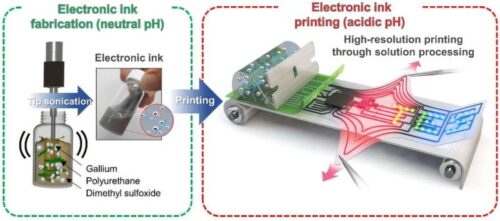

They developed a pH-controlled liquid metal ink printing process. By mixing micro-sized gallium particles into a polyurethane matrix with a neutral solvent, they made a stable, thick ink for precise printing. When heated after printing, the DMSO breaks down, creating an acidic environment that removes the oxide layer on the gallium particles. This causes the particles to join into electrically conductive networks with adjustable mechanical properties.

The printed circuits have fine details, conductivity, and a stiffness change ratio up to 1,465—letting the material switch from rigid like plastic to soft like rubber. The ink also works with common printing methods like screen printing and dip coating, enabling large-area and 3D device making.

The team showed this by creating a device that acts as a rigid portable electronic gadget under normal conditions but becomes a soft wearable health device when worn. They also made a neural probe that stays stiff during surgery for placement but softens inside brain tissue to reduce inflammation—showing promise for medical implants.

Reference: Simok Lee et al, Phase-change metal ink with pH-controlled chemical sintering for versatile and scalable fabrication of variable stiffness electronics, Science Advances (2025). DOI: 10.1126/sciadv.adv4921