It offers a sustainable alternative to traditional electronics, promising to keep more devices out of landfills.

As global e-waste surges at an alarming rate, researchers are racing to find sustainable solutions to a growing environmental crisis. A 2024 United Nations report reveals that global electronic waste has nearly doubled over the past 12 years, soaring from 34 billion to 62 billion kilograms—the equivalent of 1.55 million shipping trucks. By 2030, that number is expected to reach 82 billion kilograms. Yet only 20%—roughly 13.8 billion kilograms—is projected to be recycled, a percentage unlikely to improve.

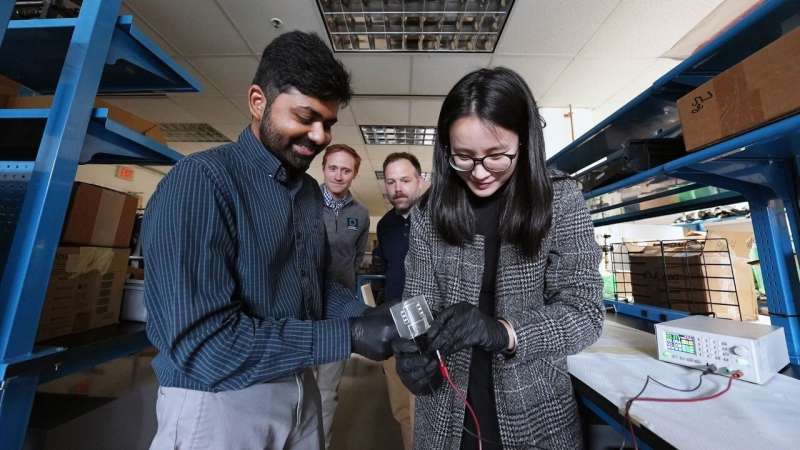

In response to this pressing issue, a team of scientists at Virginia Tech has developed a promising alternative: recyclable circuit boards that could significantly reduce the volume of electronics destined for landfills. The study showcases a class of materials designed to make electronics easier to break down and reuse.

Led by Michael Bartlett, associate professor of mechanical engineering, and Josh Worch, assistant professor of chemistry, the interdisciplinary team combined their expertise to create a recyclable, self-healing, and reconfigurable circuit material. Their innovation retains the strength and durability of traditional plastics used in circuit boards while offering a key advantage—sustainability.

The material is based on a vitrimer, a dynamic polymer that can be reshaped and recycled. Embedded with droplets of liquid metal, it conducts electricity like traditional rigid metals but with added flexibility. This unique blend allows the circuits to remain functional even when bent or damaged.

“Traditional circuit boards are made from permanent thermosets that are incredibly difficult to recycle,” said Worch. “Our composite can heal or reshape under heat without compromising performance.”

Unlike conventional recycling methods, which are energy-intensive and result in high material loss, the new boards can be efficiently broken down using alkaline hydrolysis. This process enables recovery of key components like liquid metal and LEDs, opening the door for a closed-loop system. While electronic consumption may be hard to slow, Virginia Tech’s breakthrough offers a vital step toward more sustainable electronic design—and a potential path to cutting down future e-waste.