The way to make stretchable, self-healing electronic parts can help build implantable devices that last longer and work better inside the body.

Recent technology has led to the development of many wearable and implantable devices that can monitor body signals or deliver precise treatments. Since implantable devices stay in the body for long periods, they need to be biocompatible and able to repair themselves if damaged. Researchers in South Korea, including teams from Sungkyunkwan University and the Institute for Basic Science, have developed a new way to make electronic parts that can stretch and heal themselves.

Another challenge in making implantable electronics is keeping their electrical performance stable over time, especially in wet and constantly changing conditions inside the body. To address this, the team designed materials that can stretch, heal themselves, and still work well electronically. They then developed a way to use these materials in working circuits.

The researchers introduced a scalable method to create these self-healing, stretchable transistors and circuits. This approach could help build implantable devices capable of recording signals from the brain, vagus nerve, spinal cord, peripheral nerves, and heart. Such devices could support new ways to diagnose and treat various medical conditions.

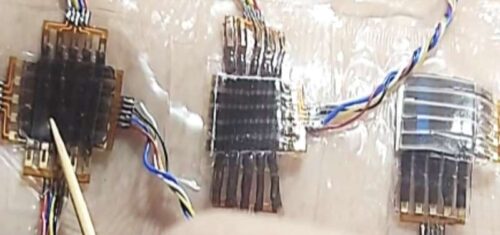

A method was proposed to build each layer of electronic devices—such as insulating films, electrodes, and semiconductor layers—over large areas using a process called transfer printing. This process can be scaled up to create large, stretchable modular systems that can be combined with touch sensors, active matrices, and displays.

With this printing method, the stretchable and self-healing transistors can be re-assembled like LEGO blocks to match different application needs. Early tests showed that these transistors, made on self-healing polymer bases with good insulation and biocompatibility, maintained stable electrical performance over long periods after being implanted in living animals.

Devices made with this approach are modular and reconfigurable, allowing easy customization and plug-and-play replacement if performance drops. This scalable method for stretchable, self-healing circuits could advance implantable and wearable biomedical devices and prosthetics. Future pre-clinical and clinical trials will help confirm their safety and real-world effectiveness.